BLOG

What Makes 6 Nylon Chips the Future of Sustainable Fashion?

As sustainability continues to gain momentum in the fashion industry, one material stands out as a game-changer: Nylon 6 chips. But what exactly are Nylon 6 chips, and why are they being hailed as the future of sustainable fashion? In this blog, we’ll explore the many reasons why Nylon 6 chips from Highsun are revolutionizing the textile industry and why this innovation matters for the future of eco-friendly manufacturing.

Understanding 6 Nylon Chips and Their Role in Fashion

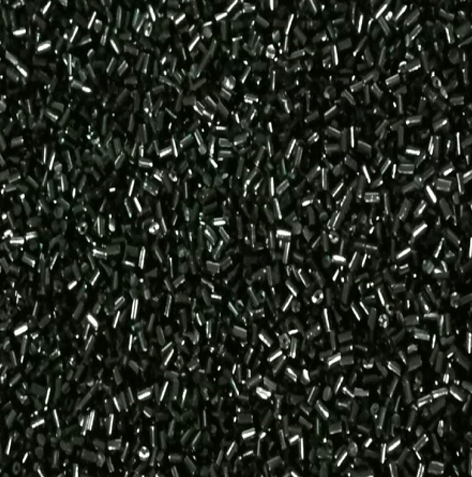

Nylon 6 chips are small, granular materials made from the polymerization of caprolactam. They are then processed into fibers, resins, and other textile components. These chips are the raw material for making high-performance products. From sportswear to technical fabrics, they are an essential part of modern manufacturing. What makes nylon 6 chips unique in the sustainable fashion space is their versatility, durability, and recyclability. This makes them a key element in creating more environmentally friendly textiles.xtiles.

The Rise of Sustainable Fashion and Nylon 6 Chips

The fashion industry has long been associated with pollution and waste. But today, brands and manufacturers are working harder than ever to incorporate sustainability into their designs. Nylon 6 chips offer a sustainable solution. They enable the production of durable, high-quality fabrics that can be recycled multiple times, reducing the need for raw materials. Highsun’s innovative manufacturing process helps create these chips, with a focus on reducing environmental impact. Without compromising quality or performance.

What’s Next for 6 Nylon Chips in the World of Advanced Polymers?

In the world of polymers, technological advancements are constantly pushing the boundaries of what’s possible. So, what does the future hold for Nylon 6 chips? With innovations in polymer chemistry and advanced manufacturing techniques, 6 Nylon chips are positioned to play an even greater role in various industries.

Innovative Manufacturing Technology at Highsun

At Highsun, innovation is at the core of every product they create. The company uses cutting-edge technology to improve the polymerization process. This ensures that the nylon 6 chips it produces have unparalleled consistency and mechanical strength. The technology not only improves the quality of the chips, but also helps reduce waste and energy consumption, making the production process more sustainable.

Expanding Applications for Nylon 6 Chips

Although nylon 6 chips have been widely used in the production of fibers and resins. But the range of potential applications for this material is expanding. New research into nylon 6’s properties and its compatibility with other materials is opening up opportunities for more diverse uses, from automotive parts to advanced medical textiles. As the demand for high-performance materials continues to increase. Nylon 6 chips are likely to become an even more integral part of a variety of industries.

What Are the Key Benefits of Using 6 Nylon Chips in Manufacturing?

The benefits of using 6 Nylon chips in manufacturing are numerous, ranging from improved product performance to reduced environmental impact. Let’s dive into some of the key advantages that make these chips an essential component in today’s high-quality products.

Unmatched Consistency and High-Quality Standards

One of the standout features of Highsun’s Nylon 6 chips is their exceptional consistency. Thanks to the company’s meticulous production processes, each batch of chips is crafted to meet strict quality standards. This consistency ensures that the end product will have the desired mechanical properties, color uniformity, and overall performance.

Manufacturers can rely on Highsun’s chips to create products that are not only durable but also aesthetically pleasing. The uniformity in color and quality means that items made from these chips will maintain their look and feel even after prolonged use, which is especially important in industries like fashion and automotive design.

Superior Mechanical Characteristics

Nylon 6 chips are known for their superior mechanical properties, including strength, resilience, and flexibility. These attributes make them ideal for applications that require high-performance materials, such as automotive components, industrial textiles, and sportswear. The mechanical strength of Nylon 6 ensures that the final products made from these chips can withstand wear and tear, making them long-lasting and reliable.

Environmental Benefits and Sustainability

In addition to their performance benefits, Nylon 6 chips also offer significant environmental advantages. The chips are recyclable, which reduces the need for new materials and lowers the carbon footprint of the manufacturing process. Furthermore, because they are produced with minimal waste, they help reduce the overall environmental impact of the production process.

What’s the Difference Between 6 Nylon Chips and Other Nylon Types?

There are different types of nylon chips available in the market, but Nylon 6 chips stand out for their unique properties and versatility. Understanding the key differences between Nylon 6 and other nylon variants can help manufacturers choose the right material for their specific needs.

Nylon 6 vs. Nylon 6,6: What’s the Difference?

The primary difference between Nylon 6 and Nylon 6,6 lies in their chemical structure. While both are high-performance polymers, Nylon 6 is made from a single monomer, caprolactam, while Nylon 6,6 is made from a combination of hexamethylenediamine and adipic acid. Nylon 6 chips are typically more flexible and easier to process than Nylon 6,6, making them ideal for applications that require high elasticity and durability.

Advantages of Nylon 6 Chips in Textile Manufacturing

Nylon 6 chips offer several advantages over other nylon types when it comes to textile production. Their superior processability, combined with their excellent strength-to-weight ratio, makes them a popular choice in the production of fabrics, fibers, and other textile components. Manufacturers can achieve a range of textures and finishes with Nylon 6, which makes it versatile enough to be used in everything from clothing to technical fabrics.

Why Choose Nylon 6 Chips from Highsun?

When you select Nylon 6 chips from Highsun, you are choosing a brand that is committed to quality, innovation, and sustainability. Here’s why manufacturers around the world trust Highsun for their Nylon 6 chip needs.

Unmatched Consistency and Quality Control

Highsun’s reputation for producing high-quality Nylon 6 chips stems from their dedication to maintaining consistent product quality. Each batch of Nylon 6 chips is manufactured to meet rigorous quality standards, ensuring that the final product will perform as expected. Whether you’re producing textiles, resins, or industrial components, Highsun’s chips provide the reliability and consistency you need to meet your customers’ demands.

Innovative Manufacturing Processes

Highsun’s commitment to innovation means they are always looking for ways to improve the manufacturing process. By leveraging the latest technologies and refining their processes, the company produces Nylon 6 chips that are more efficient to manufacture and better for the environment. This focus on innovation ensures that their products remain at the forefront of the industry, meeting the evolving needs of the market.

Comprehensive Product Range

Highsun offers a wide range of Nylon 6 chips to suit various manufacturing applications. Their product line includes raw white Nylon 6 chips, which are widely used in fibers and resins, as well as black Nylon 6 chips that provide superior color control. By offering a diverse selection of products, Highsun ensures that manufacturers can find the perfect solution for their specific needs.

Featured Products Under Nylon 6 Chips

Highsun offers a variety of Nylon 6 chips to suit different industrial applications. Two of their most popular products include:

Nylon 6-10 Chips Raw White

These raw white Nylon 6 chips are bestsellers in many applications, including fibers and resins. They offer high performance, durability, and versatility, making them ideal for a wide range of products. Whether you’re manufacturing textiles or industrial components, these chips provide the strength and reliability you need.

Nylon 6 Chips Black

Highsun’s black Nylon 6 chips are designed to meet the needs of manufacturers who require precise color control. These chips are created with advanced production technology to ensure even color distribution, making them perfect for products where color consistency is crucial.

Conclusion

Nylon 6 chips are rapidly becoming a key component in industries ranging from fashion to automotive and beyond. With their impressive mechanical properties, environmental benefits, and versatility, these chips are paving the way for more sustainable and high-performance products. When you choose Nylon 6 chips from Highsun, you are selecting a product that is backed by innovation, consistency, and a commitment to quality. Whether you are a manufacturer looking to improve the sustainability of your products or enhance their performance, Highsun’s Nylon 6 chips are the ideal choice.

LET'S TALK TOGETHER

Lorem ipsum dolor sit amet, consectetur estor adipi isicing elit, sed do eiusmod tempor este uterre incididui unt ut