BLOG

Highsun’s Nylon Chips: China’s Premium Quality for Industrial Applications

Highsun is a major player in the global industrial scene. They have earned several product design patents due to their skilled R&D team. China plays an important role in the global nylon production market. As the demand for high-quality materials rises, industries are looking for reliable sources. Highsun is responding to this need by offering advanced solutions.

The Rise of Highsun Nylon Chips

Brief History of Highsun

Highsun was founded in 1984 and is based in Fujian, China. Since its inception, Highsun has grown into a modern, multi-faceted company. It operates across several sectors, including chemical fiber, real estate, and finance. Over the years, Highsun has become a significant player in the nylon chip industry, known for its commitment to innovation and quality. As the demand for high-performance materials grew, Highsun positioned itself as a key producer of nylon chips, particularly Nylon 6/10 Chips, which are used in a wide range of applications.

Key Factors of Driving Success in the Market

One of the main factors behind Highsun’s success is its unwavering commitment to quality. The company has a dedicated quality assurance team that constantly monitors and improves production processes. This team ensures that all products meet the highest industry standards, often exceeding customer expectations. Additionally, Highsun’s emphasis on innovation allows it to stay ahead in a competitive market. The company is also known for its global reach, with production capabilities across over 30 regions worldwide. This extensive network enables Highsun to serve a diverse range of industries, meeting the growing demand for high-quality nylon products.

Premium Quality at the Core

Superior Quality Standards Upheld by Highsun

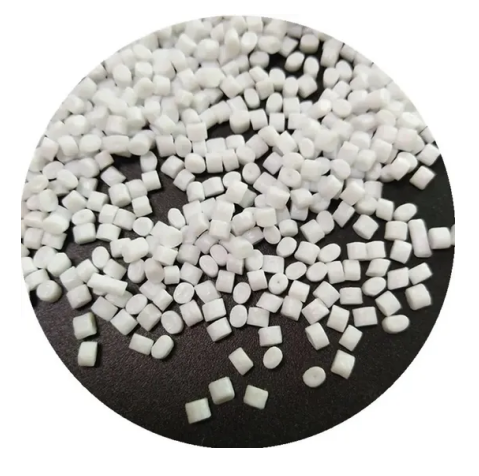

Highsun places great importance on maintaining premium quality in its products. One of the standout products is Nylon 6/10 Chips Raw White. This versatile material is widely used in the production of nylon fibers and fabrics. The chips come in three different finishes: Bright, Semi-Dull, and Full-Dull. The variations are based on the amount of titanium dioxide (TiO2) content, which affects the final appearance of the product. These options provide manufacturers with a broad range of aesthetic choices, from translucent finishes to more muted tones, allowing for both functional and decorative uses in textile applications.

Advanced Production Techniques

To ensure the consistency and reliability of its products, Highsun uses advanced production techniques. These techniques help maintain uniformity in the quality of the Nylon 6/10 Chips Raw White, whether they are used for decorative or functional purposes. The manufacturing process is carefully controlled, and the TiO2 content in each batch is monitored to guarantee the desired finish. This attention to detail ensures that the final product meets the specific needs of the textile industry, whether for items that require high transparency or those that need a more subdued, opaque finish.

Impact of Premium Quality on Performance in End-Use Applications

The premium quality of Highsun’s nylon chips plays a crucial role in the performance of end-use applications. The chips’ versatility allows manufacturers to create products that meet both aesthetic and functional requirements. Here is a breakdown of the different finishes and their uses:

Bright (BR): This finish has a 0% TiO2 content, giving it a clear, bright appearance. It is ideal for applications where a high level of transparency and brightness is needed, such as in decorative textiles or lightweight fabrics.

Semi-Dull (SD): With 0.3% TiO2 content, Semi-Dull chips offer a milk-white finish. This balance between brightness and opacity makes them suitable for applications where a softer, less reflective appearance is desired, such as in certain industrial textiles.

Full-Dull (FD): Containing 1.6% (±0.03) TiO2, Full-Dull chips have a beige-white color and a matte finish. This variant is ideal for applications where a non-reflective, neutral tone is preferred, such as in industrial uses or more subdued textile products.

Industrial Applications of Nylon Chips

Key Industries Utilizing Highsun Nylon Chips

Highsun Nylon Chips are used in many industries. They are important for making civil filament, which is spun into items like underwear, socks, and shirts. The chips are also used for spinning industrial filament, which is used in products like tire cords, canvas cords, parachutes, insulating materials, fishing nets, and safety belts. These industries rely on Highsun’s chips for their high strength and durability.

How the Chips Contribute to Efficiency, Durability, and Cost-Effectiveness

Highsun Nylon Chips help improve efficiency and reduce costs. In the textile industry, they make the production of strong fibers faster and cheaper. These benefits help companies save money while producing high-quality products. The chips’ versatility and strength contribute to both better performance and lower production costs.

Competitive Edge in the Global Market

How Highsun Stands Out

China is one of the world’s largest producers of nylon chips, and Highsun plays a crucial role in this market. The company’s competitive edge lies in its ability to provide high-quality nylon products at competitive prices. Thanks to its advanced production techniques, Highsun is able to meet the growing global demand for high-performance materials. This advantage allows the company to maintain a strong position in the global market, competing with other major players in the industry.

Highsun‘s Strategic Partnerships and Collaborations to Expand Market Reach

Highsun has developed strategic partnerships and collaborations that help expand its market reach. The company works with over 25 Fortune 500 companies across various sectors, including automotive, textiles, and electronics. These collaborations enable Highsun to produce large quantities of materials like Polyamide 6 Yarn, Spandex Yarn, Caprolactam, and Polyamide 6 Chips, which are used in numerous industries worldwide. The company’s ability to form these partnerships has played a key role in its growth and success in the global market.

Customer Testimonials and Industry Recognition

Key Customer Feedback and Testimonials from Industries

Highsun receives positive feedback from many customers in industries that rely on nylon chips. Customers praise the quality and consistency of the products, noting that the chips help improve the overall performance of their end products. Feedback highlights how Highsun’s nylon chips meet the diverse needs of various industries, from automotive parts to industrial textiles, and how they contribute to the efficiency and durability of the products they are used in.

Recognition or Awards Received by Highsun

Highsun has earned several accolades and recognition for its excellence in quality and innovation. The company has been granted over 304 national intellectual property patents. It was named a National High-Tech Enterprise and has received recognition for its contributions to the development of differentiated Polyamide 6 products. Additionally, Highsun has participated in the revision of 13 standards for the chemical fiber industry and has been involved in several national projects. These include the High Capacity PA6 High Productivity Continuous Polymerization Key Techniques project and the National 13th Five-Year Plan Program for Polyester and Polyamide Fiber Flexibility Efficient Preparative Techniques.

In Closing

Through its commitment to quality, innovation, and strategic partnerships, Highsun continues to be a leader in the nylon chip market, meeting the needs of industries worldwide.

LET'S TALK TOGETHER

Lorem ipsum dolor sit amet, consectetur estor adipi isicing elit, sed do eiusmod tempor este uterre incididui unt ut