블로그

High Tenacity Nylon Chips vs. Traditional Nylon: What Sets Them Apart?

High Tenacity Nylon Chips vs. Traditional Nylon: What Sets Them Apart?

High tenacity nylon chips are gaining prominence across industries, and for good reason. Their superior mechanical properties set them apart from traditional nylon, making them indispensable for applications where durability and performance are paramount. These chips boast higher tensile strength, ensuring they can withstand substantial forces without deformation. 또한, their enhanced resistance to wear and tear ensures longevity, even in environments subject to continuous friction or abrasion. These qualities are vital in industries such as automotive, 직물, aerospace, and heavy machinery, where materials must perform reliably under challenging conditions.

One of the key differentiators is their ability to endure extreme conditions. Whether exposed to high temperatures, heavy loads, or chemical interactions, high tenacity nylon chips maintain their structural integrity and performance. This makes them particularly valuable for critical applications, such as automotive airbags, industrial ropes, and durable textile fabrics.

Unlike traditional nylon, which may lack the robustness needed for heavy-duty applications, high tenacity nylon chips are specifically engineered for resilience. Their polymer structure is optimized during production, resulting in superior elongation and flexibility without compromising strength. This ensures that products made from these chips deliver consistent performance over time, even in demanding scenarios. For manufacturers looking to enhance the quality and reliability of their products, high tenacity nylon chips are the material of choice.

Sustainability and High Tenacity Nylon Chips: Building a Greener Future

As the global push toward sustainability intensifies, high tenacity nylon chips are emerging as a pivotal eco-friendly material. Their unique properties, combined with advanced manufacturing techniques, make them a valuable choice for industries striving to minimize environmental impact. Leading suppliers like 하이선 are setting benchmarks by employing innovative processes to reduce waste, conserve resources, and lower energy consumption during the production of Nylon 6 작은 조각.

One of the standout features of high tenacity nylon chips is their recyclability. These materials play a crucial role in fostering a circular economy, enabling manufacturers to create durable, high-performance products that comply with stringent environmental standards. Their longevity further reduces the need for frequent replacements, cutting down on material waste over time.

How Highsun Leads Sustainability Efforts

Highsun adopts cutting-edge polymerization techniques that maximize efficiency and minimize production waste. By prioritizing energy-efficient methods, Highsun ensures that their Nylon 6 chips deliver long-lasting performance, helping industries conserve resources while achieving sustainable manufacturing goals. Their commitment to innovation aligns with global sustainability trends, making their high tenacity nylon chips an ideal choice for environmentally conscious manufacturers.

What Makes High Tenacity Nylon Chips Ideal for Heavy-Duty Applications?

High tenacity nylon chips are tailored for applications requiring exceptional strength, 유연성, and reliability. Their unique properties make them ideal for use in industrial products, high-performance fabrics, and demanding environments.

Key Features of High Tenacity Nylon Chips

Superior Strength: With high tensile strength, these chips can withstand heavy loads and intense stress without deformation.

Wear Resistance: The chips are resistant to abrasion, ensuring longevity even in harsh environments.

Heat and Chemical Resistance: High tenacity nylon chips maintain their performance in extreme temperatures and resist degradation from chemicals.

These properties make them the go-to material for industries such as automotive (for airbags and seat belts), construction (for ropes and nets), and textiles (for durable fabrics).

Choosing the Right High Tenacity Nylon Chips for Your Industrial Needs

Selecting the right high tenacity nylon chips can significantly impact the quality and performance of your end products. With a broad range of options available, understanding your specific application requirements is crucial.

Why Choose Nylon 6 Chips from Highsun?

When you choose Highsun as your supplier, you gain access to:

비교할 수 없는 일관성: Highsun’s production techniques ensure uniform color and quality, essential for seamless performance in finished products.

혁신적인 제조: Advanced technology and refined processes are used to enhance the polymerization and performance of Nylon 6 작은 조각.

고품질: Stringent quality standards ensure that every batch meets or exceeds customer expectations.

Comprehensive Product Range: Highsun offers a versatile product lineup, including raw white and black Nylon 6 작은 조각, catering to diverse industrial needs.

Featured Nylon 6 Chips from Highsun

나일론 6-10 칩 흰색 칩

These raw white chips are versatile and widely used in fibers and resins. Their high-performance characteristics make them suitable for various manufacturing applications.

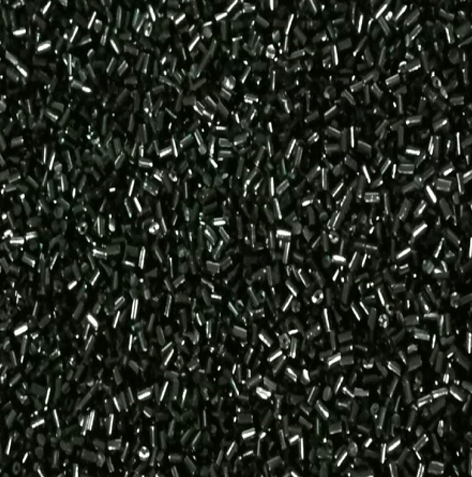

나일론 6 Chips Black

Engineered for superior color consistency, these chips are ideal for applications requiring precise color control. Highsun’s advanced production methods ensure even color distribution, resulting in a premium-quality end product.

The Future of High Tenacity Nylon Chips: Innovations and Advancements

The demand for high tenacity nylon chips is set to grow as industries continue to seek materials that offer durability, 지속 가능성, 성능. Suppliers like Highsun are at the forefront of innovation, developing new manufacturing techniques to meet evolving market needs.

Trends Shaping the Industry

Advanced Polymerization: New technologies are enhancing the molecular structure of nylon chips, resulting in even better performance.

지속 가능성 이니셔티브: Focus on eco-friendly production and recyclable materials is reshaping how nylon chips are manufactured.

사용자화: Manufacturers are offering tailored solutions to meet the specific requirements of different industries.

Why Highsun Stands Out

Highsun’s commitment to innovation and quality positions them as a leader in the high tenacity nylon chip market. Their extensive product range and dedication to sustainable practices ensure they meet the demands of modern industries while paving the way for future advancements.

결론

High tenacity nylon chips are more than just a material; they are the backbone of countless products that drive modern industries. With their superior strength, 내구성, and sustainability, they have become the material of choice for manufacturers worldwide.

When sourcing high-quality nylon chips, 하이선 stands out as a reliable partner, offering unmatched consistency, innovative manufacturing, and a comprehensive product range. As industries continue to evolve, Highsun remains committed to delivering the best solutions, ensuring their Nylon 6 chips meet the highest standards of performance and sustainability.

Whether you’re in textiles, 자동차, or heavy machinery, choosing Highsun’s high tenacity nylon chips is an investment in quality, reliability, and a greener future.

함께 이야기하자

고객은 매우 행복합니다, 팻아이싱 개발자 따라오겠습니다, 하지만 그런 시기에 자궁을 자르게 놔두세요.