Блог

Как нейлон 6 POY Supports High-Quality Yarn Production

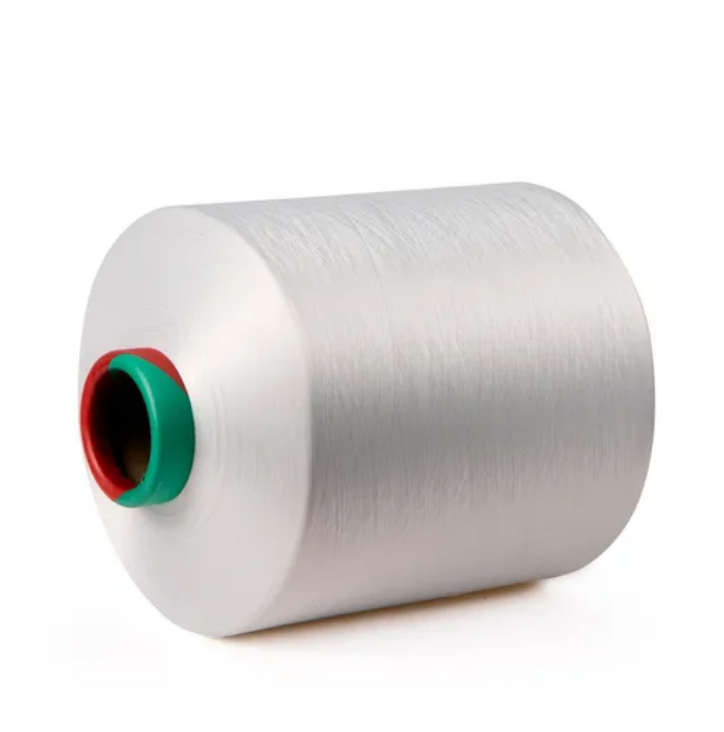

Нейлон 6 POY sits at the start of stronger, more flexible yarns – and that is precisely where Highsun focuses.

Как нейлон 6 POY Builds Strength and Flexibility Upstream

From Highsun’s vantage point as a manufacturer and solution partner, Нейлон 6 POY is not a commodity; it is a controlled “semi-processed” input that sets up drawn textured yarn (DTY) for success. In the partially oriented state, the filament carries just enough molecular order to survive speed and handling, while keeping the chain mobility needed for drawing and crimp formation later. That balance is what many mills struggle to secure at scale. Lines must run fast, stops must drop, and the fabric hand still has to feel alive. Наш нейлон 6 POY is engineered to deliver that balance so texturizers can unlock resilience without trading away softness.

• The Semi-Processed Sweet Spot

Because the yarn is intentionally kept at low orientation and low crystallinity versus fully oriented yarns, the polymer chains can realign efficiently during drawing. In practice, that means steadier denier control, cleaner crimp development, and better elastic recovery after texturizing. Even though tenacity is lower at the POY stage by design, the filament architecture remains stable, so it withstands twist, draw, and heat without the constant tuning that drains productivity. For customers searching nylon 6 POY for texturizing, this is the leverage point: the right upstream structure simplifies everything downstream.

• Ready for High- and Low-Elastic Filaments

Хайсан Нейлон 6/10 POY is prepared for conversion into both high-elastic and low-elastic filaments. One input, multiple output profiles. That flexibility helps mills serve stretch-forward athleisure, balanced everyday wear, or lightweight outerwear from a consistent base. It becomes easier to tune comfort, drape, and resilience with fewer recipe overhauls and fewer surprises on the texturizer.

Proof in Production

Consistency is the hardest promise in fiber manufacturing, so we design for it from the first minute of production. Highsun runs advanced spinning lines from Japan TMT and Germany Barmag to stabilize melt flow and quenching. Output is then checked with Uster testers and Oxford MOC NMRS instruments to verify the filament’s profile before it leaves our floor. The goal is simple: predictable material that behaves the same at startup, at hour six, and at the end of the batch.

•Strength and elongation window: 3.7-4.0 cN/dtex with elongation at 65%-72%, a range that supports durability and flexibility once the yarn is drawn and textured.

•Low orientation, low crystallinity: Designed for responsive drawing and reliable crimp formation under heat setting.

•Stable structure, smooth machining: Package stability reduces fuzz and fly, supporting higher machine speeds.

•Processing readiness: Prepared for both high-elastic and low-elastic filament pathways without chasing settings every shift.

•UV absorption enhancement: Improved ultraviolet absorption helps fabrics reach protection targets at lower thickness and weight.

•Quality control discipline: Precision tools validate lot-to-lot uniformity so process engineers can lock parameters and keep them there.

These checks are not paperwork; they are how we attack familiar pain points. Uneven crimp can ripple into elastic recovery problems. Variable dye uptake can trigger shade corrections and rework. Stop-start productivity raises labor and energy per kilo. By delivering Nylon 6 POY that is steady under draw and heat, we help reduce those hidden costs. Our customers report fewer unplanned adjustments, more stable recipe windows, and cleaner package formation that sustains speed rather than capping it.

Beyond the lab, uptime matters. A filament that resists breakage under twist and draw lets crews focus on throughput rather than firefighting. For mills that live on tight margins and tight calendars, that difference shows up in unit costs, lead times, and the headroom to pursue new programs without risking current ones. That is why we center our engineering on repeatability: reliable POY translates into reliable DTY.

Highsun Difference

Нейлон 6 POY is also a lever for design control. Highsun supplies Semi-Dull, Full-Dull, and Bright lustres so you can shape both the technical and visual profile from the first pass. That spectrum covers soft-matte everyday wear, rich body fabrics, and sleek, high-clarity textiles without resorting to heavy finishing that can dull hand feel or complicate shade matching.

1) Lustre Options and Aesthetic Control

Semi-Dull supports quiet, natural looks with smooth coverage. Full-Dull deepens the matte for denser, more even faces where glare is unwelcome. Bright delivers clarity and sheen for crisp silhouettes and vivid color. Because the base Nylon 6 POY is controlled, finishing teams gain a steadier platform for shade uniformity across lots – helping reduce shade-banding debates, re-dye cycles, and the time sink that follows when color will not cooperate.

✅ Available lustres: Semi-Dull · Full-Dull · Bright

✅ Typical uses: Athleisure, чулочно-носочные изделия, lightweight outerwear, everyday wear

2) UV Protection and Cooling at Lower Weights

Enhanced UV absorption means designers can hit protection targets with less bulk. That matters for summer sportswear, outdoor layers, and travel pieces where packability and breathability are non-negotiable. The yarn also supports a long-lasting cooling effect that helps garments feel fresh in warm conditions – without loading the fabric with heavy add-ons. For mills, this opens a path to lighter constructions and simpler finishes that still meet performance briefs. Less mass, fewer steps, more comfort.

Highsun does not ask you to trade performance for practicality. Наш нейлон 6/10 POY is built so you can scale programs with confidence: the same strength-elongation window, the same processing behavior, the same visual outcomes. When you pivot from a high-elastic line to a balanced everyday fabric, you do not have to relearn the material. That familiarity saves changeover time and reduces scrap.

Why Highsun, and why now? We combine controlled orientation with rigorous testing to deliver a Nylon 6 POY that draws cleanly, textures reliably, and integrates across your product map. The features you expect – 3.7-4.0 cN/dtex strength, 65%-72% удлинение, low orientation and crystallinity, UV absorption enhancement – are backed by equipment and instruments that keep them within range day after day. If you are searching for a dependable nylon 6 POY yarn supplier, consider what consistency would do for your yield, energy per kilo, and delivery promises.

Call to action – Bring predictable performance to your line.

Talk with Highsun’s engineers about trial packages, spec matching, or switching guidance for existing DTY recipes. Request a sample cone and a technical data sheet, and see how our Nylon 6 POY helps you achieve yarn strength and flexibility without the usual production friction.

ПОГОВОРИМ ВМЕСТЕ

Клиент очень доволен, За мной будет следить разработчик жирной глазури, но пусть утроба будет разрезана в такое время, чтобы