BLOG

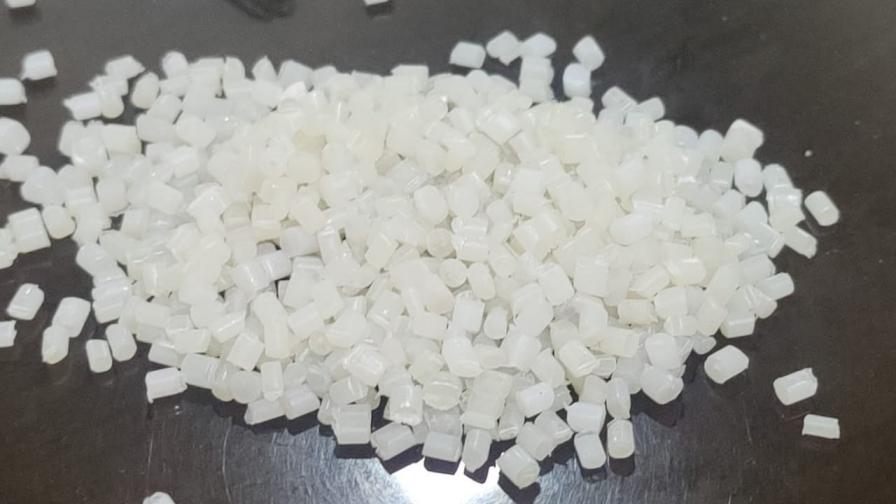

Why Choose PA6 Polyamide Chips for Your Next Project?

PA6 Polyamide (Nylon 6) chips are essential across various industries today. These chips are widely used in sectors such as automotive, textiles, and electronics. As the demand for high-performance materials rises, companies require stronger and more durable solutions for their projects. PA6 chips meet these needs, offering a blend of strength, flexibility, and reliability. Studies indicate that the adoption of PA6 is on the rise, driven by its cost-effectiveness and impressive performance characteristics. This combination makes PA6 an increasingly popular choice for contemporary applications.

What is PA6 Polyamide?

PA6 Polyamide, also known as Nylon 6, is a versatile plastic widely used in various industries. It is produced through the polymerization of caprolactam, a material that forms long chains, giving PA6 its distinct properties.

Renowned for its strength and flexibility, PA6 is resistant to wear, making it ideal for a range of applications. This combination of qualities makes PA6 a go-to material in industries such as automotive, textiles, and electronics. It is well-suited for enduring harsh conditions while maintaining its structural integrity over time.

Understanding PA6 Polyamide (Nylon 6)

PA6, or Nylon 6, is a synthetic polymer made through polymerization, where caprolactam molecules link together to form long chains. These chains provide the material with strength and other beneficial properties. PA6 is commonly used to produce fibers, films, and engineering plastics, known for being lightweight, durable, and resistant to wear—qualities that make it a preferred choice across numerous industries.

Manufacturing Process: Polymerization of Caprolactam

The production of PA6 begins with heating caprolactam, which undergoes polymerization, linking molecules into long polymer chains. These chains endow PA6 with desirable properties, such as durability, flexibility, and resistance to wear. This process is carefully controlled to ensure that the final material meets the required quality standards.

Key Features

PA6 Polyamide stands out for its durability, flexibility, and resistance to wear. It can withstand heat, chemical exposure, and physical stress, making it ideal for demanding applications such as gears, bearings, and automotive parts. The material maintains its shape even under pressure, contributing to its widespread use in various industries.

Cost-Effectiveness and Versatility

PA6 chips offer a cost-effective solution for many manufacturers. The raw materials required to produce PA6 are relatively inexpensive, which helps keep the overall cost of producing PA6 products low. Its strength and durability make it an affordable choice where other materials might be too expensive or less reliable.

Why PA6 Chips are a Cost-Effective Choice

PA6 offers an excellent balance between performance and price. It is more affordable than many other high-performance materials yet still provides superior strength, durability, and flexibility. Additionally, the well-established production process for PA6 helps reduce manufacturing costs, making it a smart choice for businesses looking to optimize their spending while ensuring product quality.

Versatility in Molding and Extrusion

PA6 chips are highly adaptable in molding and extrusion processes. They can be molded into a variety of shapes, such as sheets, films, or parts, and can also be extruded into long forms like pipes, rods, or profiles. This versatility makes PA6 a great material for producing a wide range of products, from automotive components to textiles.

Reliable Choice of PA6 Polyamide Chips

When you choose Nylon 6 chips from Hengsheng, you are assured of high-quality products. Our refined production process minimizes variations in color and quality, ensuring each batch is consistent. This consistency is crucial for creating products that not only perform well but also maintain visual appeal.

High-Quality Production Process

We use advanced technology and precise processes to manufacture our Nylon 6 chips, ensuring high mechanical strength and superior quality. Our commitment to innovation allows us to deliver consistent products that meet the strictest quality standards, ensuring customer satisfaction.

Types of Nylon 6 Chips

Hengsheng offers a range of Nylon 6 chips to meet various needs. Our standard white chips are widely used, while black Nylon 6 chips offer superior color matching for specific applications. These chips are known for their reliable performance across industries.

Nylon 6/10 Chips Raw White Variants

Our Nylon 6/10 Raw White chips come in three finishes: Bright, Semi-Dull, and Full-Dull. Each finish has a different titanium dioxide (TiO2) content, which influences the final product’s appearance:

- Bright (BR): No TiO2, offering a transparent and bright finish, ideal for applications needing clarity.

- Semi-Dull (SD): Contains 0.3% TiO2, providing a softer, milky white look that balances opacity and brightness.

- Full-Dull (FD): With 1.6% TiO2, these chips give a beige-white, matte finish perfect for neutral-toned applications.

These finishes cater to different requirements in textile production, combining both functional and aesthetic qualities.

Applications

PA6 Polyamide chips are commonly used in spinning civil filaments, which are essential for manufacturing products like underwear, socks, and shirts. PA6’s strength and flexibility make it an ideal material for fabrics that need to be durable yet comfortable. It is soft enough for clothing while providing long-lasting wear, making it a key material in high-quality textiles.

Civil Filament Uses

PA6 fibers are widely used in the fashion industry for everyday clothing. Their smooth texture and durability make them perfect for socks, shirts, and other garments. Additionally, PA6 filaments are breathable, enhancing comfort, while their strength ensures long-term performance.

Industrial Filament Uses

PA6 Polyamide chips are also used to produce industrial filaments for products like tire cords, canvas, parachutes, fishing nets, safety belts, and insulating materials. The strength and wear resistance of PA6 make it an excellent choice for high-stress, heavy-duty applications, ensuring reliable performance across various industries.

Storage of Nylon 6 Chips

Proper storage is essential to maintaining the quality of Nylon 6 chips. They should be kept in a cool, dry place to avoid damage from heat or moisture, as exposure to extreme conditions can affect the material’s performance.

Ideal Storage Conditions

The best environment for storing Nylon 6 chips is a cool and dry area. High temperatures and moisture can degrade the material, so storing it in a stable environment ensures the chips retain their strength and flexibility for future use.

Protect from Sunlight and Rain

To preserve the quality of Nylon 6 chips, they should be kept out of direct sunlight and rain. Exposure to sunlight can cause the material to break down, while rain can introduce moisture, both of which can degrade the chips. Storing them in a sheltered area helps avoid these risks and keeps them in optimal condition.

Get Started with Highsun PA6 Polyamide Chips Today!

Highsun Nylon 6 chips are known for their versatility and reliability, making them ideal for both civil and industrial applications. To maintain their quality and performance, it’s essential to store and handle them properly. Always store the chips in a cool, dry environment and protect the packaging during transport.

Ready to incorporate Nylon 6 chips into your project? Reach out to us today. Our team is here to assist you in finding the best solutions. Don’t delay—ensure your materials are stored and handled correctly for optimal results!

LET'S TALK TOGETHER

Lorem ipsum dolor sit amet, consectetur estor adipi isicing elit, sed do eiusmod tempor este uterre incididui unt ut