Blog

A Deep Dive into Polyamide Chips Nylon 6 Monofilament

Have you ever wondered what makes certain fabrics incredibly strong yet lightweight, or why some industrial materials can withstand extreme conditions without faltering? The answer lies in a remarkable innovation: polyamide chips nylon 6 monofilament. This versatile material is changing the landscape of textiles and industrial applications, proving indispensable in various sectors.

Understanding Polyamide Chips Nylon 6 Monofilament

What Are Polyamide Chips?

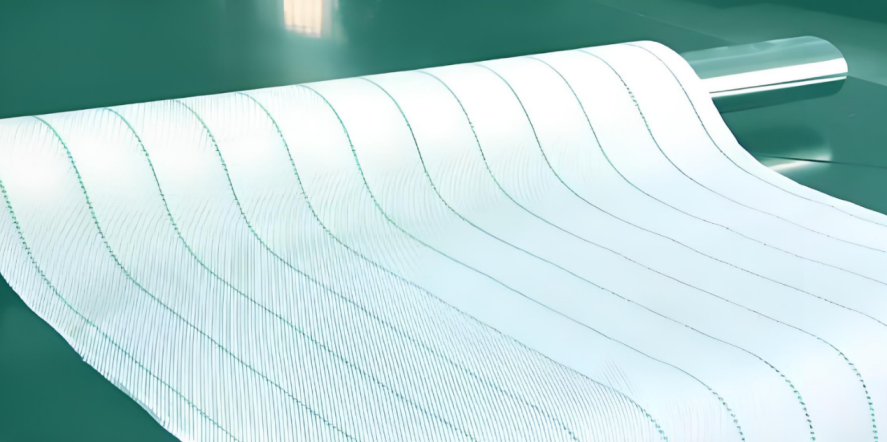

Polyamide chips are small, granulated forms of nylon, specifically nylon 6, used primarily in the production of high-performance fibers. These chips are the building blocks for creating nylon 6 monofilament, which is characterized by its single-strand structure and exceptional strength.

The Essence of Nylon 6 Monofilament

Nylon 6 is a synthetic polymer known for its durability and resilience. When processed into monofilament, it transforms into a material suitable for a variety of applications, ranging from fishing lines to industrial textiles. Its unique properties stem from the molecular structure of nylon, providing an array of benefits that meet the rigorous demands of industrial applications.

Highsun: A Leader in Nylon 6 Production

Rooted in Fujian, Chine, since 1984, Highsun Holding Corporation has established itself as a leading manufacturer of synthetic chemical fibers, including nylon 6 chips and monofilament. With a commitment to quality and sustainability, Highsun caters to the needs of clients across more than 30 Régions du monde entier, partnering with 25 of the world’s top 500 entreprise. Their comprehensive industrial chain—from cyclohexanone to dyeing and finishing—ensures a steady supply of high-quality products.

Features of Polyamide Chips Nylon 6 Monofilament

Haute Ténacité: Strength You Can Rely On

One of the standout features of nylon 6 monofilament is its high tenacity, boasting a tensile strength of up to 54 cN/tex. This remarkable strength allows it to withstand significant stress and strain, making it ideal for demanding applications where durability is paramount.

Abrasion and Tear Resistance: Built to Last

Nylon 6 monofilament exhibits exceptional abrasion and tear resistance. This feature ensures that products made from this material can endure repeated use in harsh environments without showing signs of wear. Industries that require long-lasting materials, such as outdoor gear and automotive applications, greatly benefit from this characteristic.

Size Stability and Consistent Quality

Another advantage of nylon 6 monofilament is its size stability. The material maintains its dimensions under various environmental conditions, ensuring reliable performance and quality in end products. This stability is crucial for applications that require precision, such as medical devices and high-performance textiles.

Addressing Industrial Needs with Nylon 6 Monofilament

Versatility Across Industries

Nylon 6 monofilament is not just a one-trick pony; its versatility makes it suitable for a broad range of applications. From fishing lines to industrial fabrics, the capabilities of nylon 6 monofilament extend far and wide, providing solutions tailored to specific industry needs.

Engineering and Construction Applications

In the engineering and construction sectors, nylon 6 monofilament is often used in reinforced composites and geotextiles. Its high strength and durability allow it to be used in applications where structural integrity is vital, such as in the construction of retaining walls and road stabilization.

Textile Innovations: Fashion Meets Function

In the world of fashion and textiles, nylon 6 monofilament has opened new avenues for innovative designs. High-tenacity yarns are used in creating performance fabrics that combine style with functionality. From sportswear to outdoor gear, the durability of nylon 6 ensures that these fabrics withstand the rigors of active lifestyles.

Fonctions du fil de nylon haute ténacité

Exceptional Performance in Diverse Applications

Nylon high-tenacity yarn is celebrated for its unparalleled performance across a range of applications. Its ability to endure high stress and strain makes it the go-to choice for products requiring superior reliability. This characteristic is essential in fields where safety and performance are non-negotiable.

Ideal for Industrial Fabrics

In the realm of industrial fabrics, nylon 6 high-tenacity yarn is frequently utilized to manufacture heavy-duty textiles. These fabrics are used in various applications, from tarpaulins to automotive upholstery, ensuring they can withstand wear and tear while maintaining their aesthetic appeal.

Reinforced Composites and High-Strength Threads

The high strength of nylon 6 makes it an excellent choice for reinforced composites and sewing threads. In industries where precision and durability are critical, such as aerospace and automotive, nylon high-tenacity yarn provides the necessary strength and reliability, ensuring products perform as expected under demanding conditions.

Environmental Benefits of Nylon 6 Monofilament

Energy Efficiency in Production

One of the notable benefits of nylon 6 high-tenacity yarn is its environmentally friendly production process. Unlike other yarns that require extensive dyeing processes, nylon 6 can be produced using a no-dyeing method. This approach significantly reduces energy consumption and minimizes the emission of pollutants, making it a sustainable choice for manufacturers.

Intégration moléculaire améliorée

The dope dyeing and in-situ polymerization processes employed in the production of nylon 6 enhance the molecular integration of colored fibers. This not only improves the strength of the yarn but also ensures that the color remains consistent throughout its use, reducing the need for additional treatments that could harm the environment.

Commitment to Sustainability

Highsun’s dedication to environmental stewardship is evident in its practices. By focusing on energy-efficient production methods and sustainable materials, the company contributes to a more sustainable future while meeting the needs of its diverse clientele.

Conclusion: The Future of Polyamide Chips Nylon 6 Monofilament

Polyamide chips nylon 6 monofilament represents a significant advancement in material technology, offering exceptional strength, durabilité, and versatility. As industries continue to evolve and demand more robust solutions, the importance of materials like nylon 6 cannot be overstated.

With Highsun leading the charge in innovation and sustainability, the future looks bright for nylon 6 monofilament. Its applications are vast and varied, serving as a testament to the material’s ability to meet the challenges of modern manufacturing and production. As we look ahead, the potential for further developments in this field is exciting, promising to redefine standards across numerous industries.

In an era where performance and sustainability are paramount, polyamide chips nylon 6 monofilament stands out as a clear choice for manufacturers and consumers alike. Whether you’re in textiles, construction, or beyond, this remarkable material is ready to meet your needs head-on.

PARLONS ENSEMBLE

Le client est très content, Je serai suivi par le développeur fat isicing, mais que l'utérus soit coupé en un temps tel que